Dyeing of Oriental Rugs

The wool is spun before being dyed. In the case of high-quality rugs from the Middle East, this is usually done by hand made from sheep's wool. Wool has a natural fat content that protects against dirt, moisture and wear.

Natural materials are the original source for the dyeing of wool. Even today, many Persian rugs are still dyed from natural materials. It is very complex and can take up to fourteen days until the desired colour has been achieved. In comparison to chemical dyes, natural dyes give the wool a shine that can hardly be surpassed. In addition, the dyestuffs are absolutely harmless and are very popular again.

Various plant and natural materials used for dyeing wool

Colour pigments in a clay bowl

Dyeing of wool yarns in Morocco

After dyeing, the yarn is dried in the sun. This produces a beautiful soft, slightly faded sheen with natural colours. In the case of synthetic colours, the entire dyeing process is usually many times faster and is therefore often used for cheaper rugs from the Orient. Drying can take several days and is carried out either on a stone floor or on scaffolding, as shown in the photo.

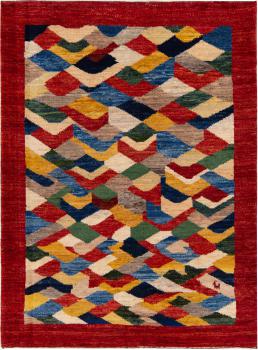

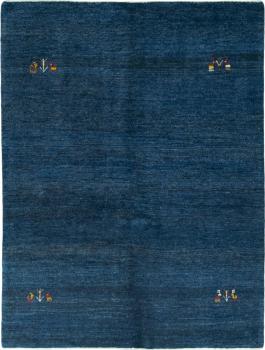

Examples of plant-dyed Rugs

These rugs have been provided from an assortment of over 9.500 different vegetable coloured Persian rugs by Nain Trading from Hamburg. Hamburg, Germany is still the most important hub for the trade of oriental rugs in the Western World with Nain Trading offering one of the largest assortments of handmade oriental carpets worldwide.

Production in Detail

Centuries-old tradition is the basis of almost every Oriental rug. Long ago Persian rugs were already considered the highest luxury...

Read more

Whether sheep wool, silk or cotton, the material of a hand-knotted oriental rug usually comes from nature...

Read more

The colours of many high-quality oriental carpets still originate today from plants and minerals...

Read more

No matter how detailed the pattern may be, some knotters still craft the rug from memory today...

Read more

An art that has been perfected over many centuries and is still unrivalled today...

Read more

Colour facets, durability, level of detail are only a few of the differences to machine-made rugs...

Read more